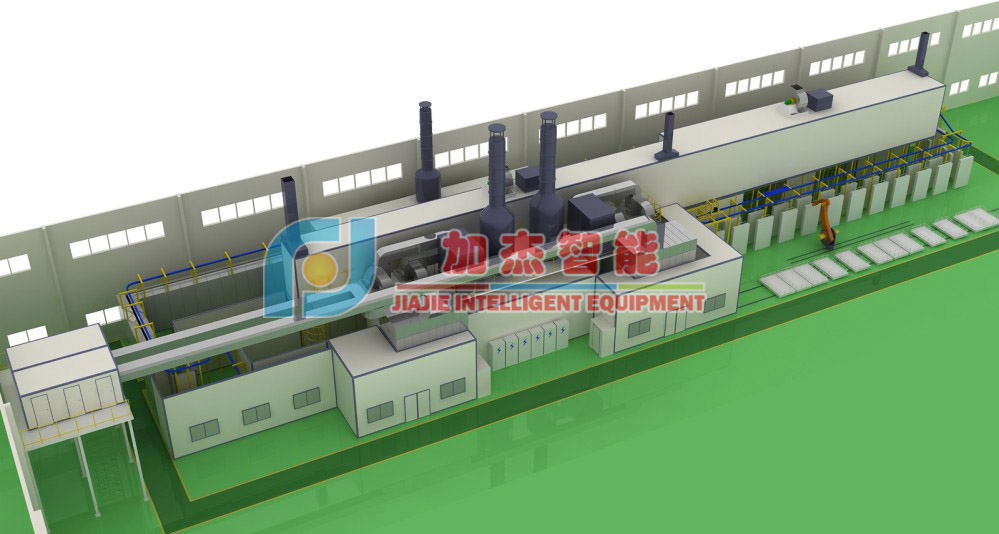

Drying and curing equipment is mainly composed of drying chamber, heating system and temperature control. The drying chamber body has through type, through type; Heating system heating mode is fuel (heavy oil, light oil), gas (natural gas, liquefied gas), electric heating (far infrared, electric heating), steam, and so on.

Drying and curing equipment relatively few problems, but in the heat preservation and energy saving and safety aspects should still cause attention.

The external surface temperature of drying chamber is too high

Improper selection of thermal insulation materials is the main reason for poor thermal insulation effect, excessive surface temperature and unsatisfactory thermal insulation performance. This not only increases energy consumption, but also fails to meet the requirements of Article 5.9.2 in the National standard GB1444321993 "Safety Regulations for Coating Operation" : the drying room should have good insulation, and the surface temperature of the outer wall should not be higher than room temperature 15℃.

2. The exhaust pipe is improperly set or not set

The exhaust pipe of the drying and curing room of some coating lines is not connected to the outside, but in the workshop, the waste gas is directly discharged into the workshop, causing air pollution in the workshop; The exhaust outlet of the drying and curing chamber of some coating lines is not set in the position with the highest concentration of exhaust gas, which is not conducive to the rapid discharge of exhaust gas and the prevention of accumulation. It also does not meet the requirements of national standard GB1444321993 article 5.1.6: The exhaust outlet of the drying room should be set in the area with the highest concentration of combustible gas. After spraying the workpiece into the drying and curing room, because the paint contains organic solvents to varying degrees, the drying and curing process will produce organic solvent waste gas, organic solvent waste gas has flammability, if the waste gas is not discharged from the drying room in time and accumulated in the drying room, once the concentration is too high will cause safety hazards.

客戶服務(wù)熱線

客戶服務(wù)熱線